Here are a few things to consider when choosing LED light bulbs...

Efficiency, Colour Temperature, Colour Rendering, Heat Output, lifetime, etc.

How many kinds of dead lights are there in LED?

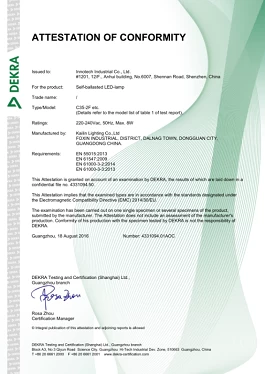

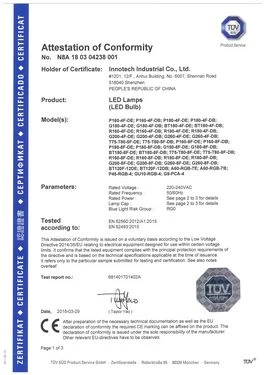

Innotech

Innolite

2018-03-12 11:05:30

01.Poor antistatic ability of the chip

LED(LED bulbs for home) anti-static index depends on the LED chip itself, and the package material is expected to package process unrelated, or influence factors are very small, very small; the LED lamp is more vulnerable to electrostatic damage, which is related with the two pin spacing, LED chip of the bare wafer two electrode spacing is very small, generally is less than one hundred microns, and the LED pin is about two mm, when the electrostatic charge transfer, the greater the spacing, the easier the formation of large potential difference voltage is high. Therefore, after sealing the LED lamp, it is often more likely to have a static damage accident.

LED epitaxial films at high temperature in the crystal growth process, substrate, MOCVD reaction cavity residual sediment, peripheral gas and Mo source are introducing impurities, these impurities will penetrate into the epitaxial layer, prevent GaN crystal nucleation, the formation of a variety of epitaxial defects in the epitaxial layer, the final surface form small potholes, these are also serious effect of crystal quality and properties of epitaxial wafer thin film materials.

Electrode processing is the key process to make LED(LED Panel Downlight manufacturer china) chips, including cleaning, evaporation, yellow light, chemical etching, fusion and lapping. It will touch many chemical cleaning agents. If chip cleaning is not clean enough, it will make harmful chemicals residues. These harmful chemicals in LED power, electrochemical reaction and electrode, resulting in death, light attenuation, dark light, blackening phenomenon. Therefore, it is very important to identify the chemical residues of the chip for the LED packaging plant.

The damage of LED chip will lead to the failure of LED(Opal Plastic LED light bulbs) directly, so it is very important to improve the reliability of LED chip. In the process of evaporation, the chip is sometimes fixed with a spring clip, so a clip can be produced. If the yellow light is not fully developed and the mask has a hole, there will be more metal in the luminous area. During the process of pre production, all processes such as cleaning, evaporation, yellow light, chemical etching, fusion and grinding must use tweezers and flower basket, carrier and so on. Therefore, there will be a scratch on the grain electrode.

Effect of chip electrode on the chip electrode itself: solder deposition is not solid, resulting in wire electrode loss or damage; the chip electrode itself will lead to poor weldability, welding ball weld; chip storage improper oxidation electrode surface, surface contamination and so on, the bonding surface of slight pollution may affect the metal atoms between the two the diffusion caused by failure or weld.

The new structure of the LED chip electrode has a layer of aluminum, which acts as a mirror to form a mirror in the electrode to improve the efficiency of the chip. Secondly, it can reduce the amount of gold used to evaporate the electrode and reduce the cost to a certain extent. But aluminum is a relatively active metal. Once the packaging plant is controlled strictly, the aluminum reflective layer in the gold electrode will react with chlorine in the glue, resulting in corrosion.

LED(LED bulbs for home) anti-static index depends on the LED chip itself, and the package material is expected to package process unrelated, or influence factors are very small, very small; the LED lamp is more vulnerable to electrostatic damage, which is related with the two pin spacing, LED chip of the bare wafer two electrode spacing is very small, generally is less than one hundred microns, and the LED pin is about two mm, when the electrostatic charge transfer, the greater the spacing, the easier the formation of large potential difference voltage is high. Therefore, after sealing the LED lamp, it is often more likely to have a static damage accident.

02.chip epitaxy defects

LED epitaxial films at high temperature in the crystal growth process, substrate, MOCVD reaction cavity residual sediment, peripheral gas and Mo source are introducing impurities, these impurities will penetrate into the epitaxial layer, prevent GaN crystal nucleation, the formation of a variety of epitaxial defects in the epitaxial layer, the final surface form small potholes, these are also serious effect of crystal quality and properties of epitaxial wafer thin film materials.

03. Residue of chip chemical

Electrode processing is the key process to make LED(LED Panel Downlight manufacturer china) chips, including cleaning, evaporation, yellow light, chemical etching, fusion and lapping. It will touch many chemical cleaning agents. If chip cleaning is not clean enough, it will make harmful chemicals residues. These harmful chemicals in LED power, electrochemical reaction and electrode, resulting in death, light attenuation, dark light, blackening phenomenon. Therefore, it is very important to identify the chemical residues of the chip for the LED packaging plant.

04.the damage of the chip

The damage of LED chip will lead to the failure of LED(Opal Plastic LED light bulbs) directly, so it is very important to improve the reliability of LED chip. In the process of evaporation, the chip is sometimes fixed with a spring clip, so a clip can be produced. If the yellow light is not fully developed and the mask has a hole, there will be more metal in the luminous area. During the process of pre production, all processes such as cleaning, evaporation, yellow light, chemical etching, fusion and grinding must use tweezers and flower basket, carrier and so on. Therefore, there will be a scratch on the grain electrode.

Effect of chip electrode on the chip electrode itself: solder deposition is not solid, resulting in wire electrode loss or damage; the chip electrode itself will lead to poor weldability, welding ball weld; chip storage improper oxidation electrode surface, surface contamination and so on, the bonding surface of slight pollution may affect the metal atoms between the two the diffusion caused by failure or weld.

05.The incompatibility of the new structure process chip and the light source material

The new structure of the LED chip electrode has a layer of aluminum, which acts as a mirror to form a mirror in the electrode to improve the efficiency of the chip. Secondly, it can reduce the amount of gold used to evaporate the electrode and reduce the cost to a certain extent. But aluminum is a relatively active metal. Once the packaging plant is controlled strictly, the aluminum reflective layer in the gold electrode will react with chlorine in the glue, resulting in corrosion.

+

+