Here are a few things to consider when choosing LED light bulbs...

Efficiency, Colour Temperature, Colour Rendering, Heat Output, lifetime, etc.

LED lamp invention

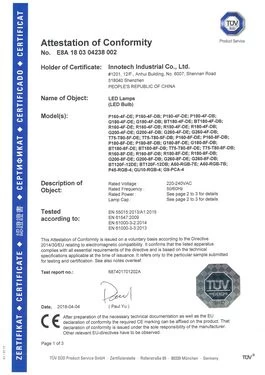

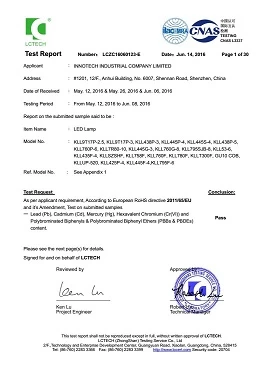

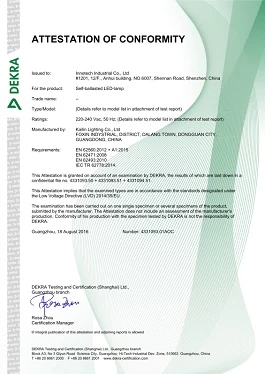

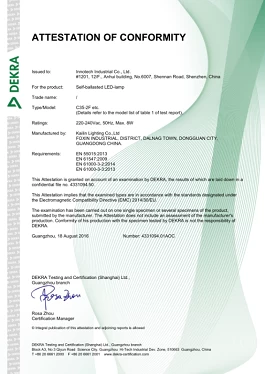

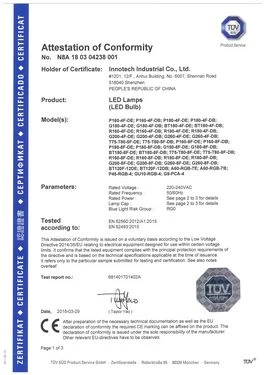

Innotech

Innotech

2018-09-17 17:53:19

In 1993, Shuji Naka, who worked at Nichia Corporation in Japan (Sriji Naka)

Mura) invented a commercially available blue LED based on the wide bandgap semiconductor materials gallium nitride (GaN) and indium nitride (InGaN), which were widely used in the late 1990s. In theory, blue LEDs can produce white light in combination with the original red and green LEDs, but white LEDs are rarely created in this way.

Most of the currently produced white LEDs are made by coating a layer of light yellow phosphor on a blue LED (near-UV, wavelength 450nm to 470nm). This yellow phosphor is usually made by mixing germanium with germanium. Aluminum garnet (Ce3+:YAG) crystals are ground into a powder and mixed in a dense binder. When the LED chip emits blue light, part of the blue light is efficiently converted by the crystal into a predominantly yellow light with a broad spectrum (about 580 nm in the center of the spectrum). (In fact, single crystal Ce-doped YAG is considered to be a scintillator more than a phosphor.)

Since yellow light stimulates the red and green receptors in the naked eye, the blue light of the LED itself is mixed to make it look like white light, and its color is often called "white of moonlight." This method of making white LEDs was developed by Nichia Corporation and has been used in the production of white LEDs since 1996. To adjust the color of light yellow light, other rare earth metal lanthanum or lanthanum can be used to replace the cerium (Ce) incorporated in Ce3+:YAG, or even to replace some or all of the aluminum in YAG. Based on the characteristics of the spectrum, red and green objects appear to be less vivid under the illumination of the broad spectrum source. In addition, due to variations in production conditions, the color temperature of the finished product of this LED is not uniform, from warm yellow to cold blue, so it will be distinguished by its characteristics during the production process.

Another method of making white LEDs is a bit like a fluorescent lamp. LEDs that emit near-ultraviolet light are coated with a mixture of two phosphors, one that emits red and blue light, and one that emits green light. Copper and aluminum doped with zinc sulfide (ZnS). However, since the ultraviolet rays cause cracking and deterioration of the epoxy resin in the adhesive, the production is difficult and the life is short. Compared with the first method, it is less efficient and produces more heat (because StokesShift is larger), but the advantage is that the characteristics of the spectrum are better, and the light produced is better. Since the LED power of the ultraviolet light is higher, the efficiency is lower than that of the first method, and the brightness is similar.

The latest method of making white LEDs does not use phosphors. A new approach is to grow an epitaxial layer of zinc selenide on a zinc selenide (ZnSe) substrate. When energized, its active zone emits blue light and the substrate glows yellow, mixing it with white light.

With brand name “INNOLITE®”, Innotech Industrial Co., Ltd. was founded in Shenzhen, the first Special Economic Zone in China, in 2001.We have LED panel downlight supplier, Vintage LED filament bulbs Diamond, Antique LED filament bulbs Lantern, Antique LED filament bulbs Lantern China, G80 Antique LED filament bulbs.

+

+