Here are a few things to consider when choosing LED light bulbs...

Efficiency, Colour Temperature, Colour Rendering, Heat Output, lifetime, etc.

Tips to improve LED cooling efficiency

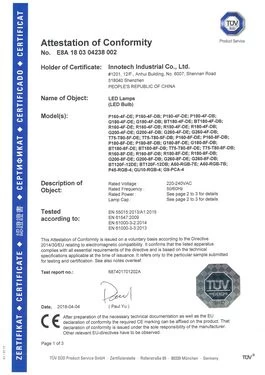

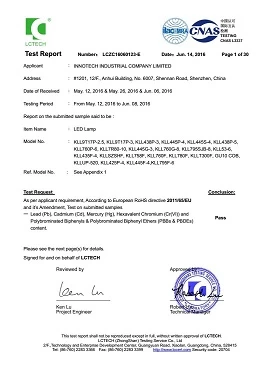

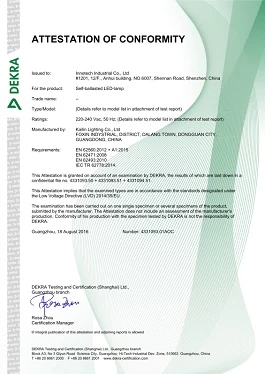

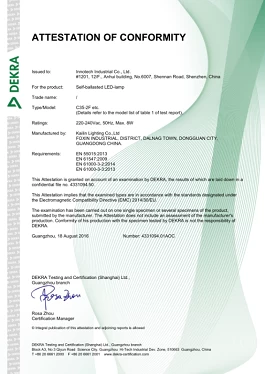

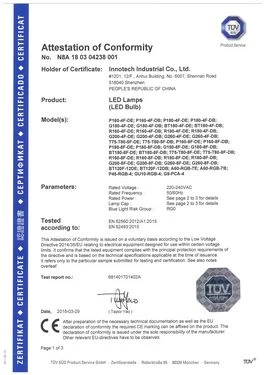

Innotech

Innolite

2018-02-01 08:55:52

Engaged in LED lighting design and production, it will certainly be exposed to safety and regulatory issues. Cooling is a part of safety certification. The quality of the heat is directly related to the life of LED lighting equipment, the temperature is too high will cause the deposit of heat on the chip, affecting its work. So how to improve the cooling level of LED(best led bulbs supplier) lamps?

LED lighting power, determines the need to consider the extent of the problem of heat dissipation, power LED refers to the working current of 100 mA or more light-emitting diodes, is our standard line with the United States ASSIST Union defined by the existing two kinds of LED's are To 2.1V and 3.3V typical voltage, that is, the input power of 210MW and 330MW LED above are power LED, you need to consider the device thermal dispersion problems. Some people may have different views, but practice has proved that to improve the reliability of power LED, it is necessary to consider the power LED heat dissipation. LED cooling and the main parameters related to thermal resistance, junction temperature and temperature rise. Thermal resistance is the difference between the effective temperature of the device and the externally specified reference temperature divided by the steady-state power dissipation in the device. It is the most important parameter that indicates the degree of heat dissipation of the device. At present, the thermal resistance of the power LED with good thermal dissipation is less than or equal to 10 ℃ / W. The best thermal resistance reported in China is ≤5 ℃ / W and the thermal resistance abroad is ≤3 ℃ / W. If this level is achieved, the lifetime of the power LED can be ensured .

Junction temperature refers to the temperature of the semiconductor junction in the main heat-emitting part of the LED device. It is reflected in the working conditions of LED devices, can withstand the temperature value. Chip and phosphor heat resistance is still very high, has reached the chip junction temperature at 150 ℃, the phosphor at 130 ℃, the basic life of the device will not have any effect. The higher the chip phosphor heat resistance, the lower the thermal requirements. Temperature rise there are several different temperature rise, we are discussing here is: Case - ambient temperature it refers to the LED(LED bulbs energy saving china) device package (LED lamps can be measured the hottest spot) Temperature and environment (in the light emitting plane, 0.5 meters away from the lamp) temperature difference.

It is a direct measurement of the temperature, and can directly reflect the extent of the LED device cooling, practice has proved that the ambient temperature is 30 ℃, if the measured LED tube is 60 ℃, the temperature should be 30 ℃ , This time can basically ensure the life of LED devices, such as temperature rise is too high, LED light source maintenance rate will be significantly reduced. In order to improve the level of heat dissipation we provide the following suggestions, from the LED chip, to take a new structure, new technology, improve the thermal resistance of LED chip junction temperature, and other materials, heat resistance, making the cooling requirements reduced. Better thermal properties of new materials, including bonding materials between metals, phosphors and other mixed plastic, making the thermal resistance ≤ 10 ℃ / W or lower.

Reduce heating, as far as possible the use of good thermal conductivity of the cooling material, the design requirements have better ventilation channels, so that the heat dissipated as soon as possible, the required temperature should be less than 30 ℃. In addition, to improve the cooling of modular lighting should mention the agenda up. Many ways to dissipate heat, such as the use of heat pipes, of course, very good, but to consider the cost factor, the cost should be considered in the design issues.

In addition, LED lighting design in addition to improve lamp efficiency, light distribution requirements, beautiful appearance, to improve the heat level, the use of good thermal conductivity of the material, the radiator coated with certain nano-materials, the thermal conductivity increased by 30%. In addition, to have better mechanical properties and tightness, but also dust-proof radiator, LED lamps require temperature rise should be less than 30 ℃.

If you want to know more information, you can click LED light bulbs manufacturer china.

LED lighting power, determines the need to consider the extent of the problem of heat dissipation, power LED refers to the working current of 100 mA or more light-emitting diodes, is our standard line with the United States ASSIST Union defined by the existing two kinds of LED's are To 2.1V and 3.3V typical voltage, that is, the input power of 210MW and 330MW LED above are power LED, you need to consider the device thermal dispersion problems. Some people may have different views, but practice has proved that to improve the reliability of power LED, it is necessary to consider the power LED heat dissipation. LED cooling and the main parameters related to thermal resistance, junction temperature and temperature rise. Thermal resistance is the difference between the effective temperature of the device and the externally specified reference temperature divided by the steady-state power dissipation in the device. It is the most important parameter that indicates the degree of heat dissipation of the device. At present, the thermal resistance of the power LED with good thermal dissipation is less than or equal to 10 ℃ / W. The best thermal resistance reported in China is ≤5 ℃ / W and the thermal resistance abroad is ≤3 ℃ / W. If this level is achieved, the lifetime of the power LED can be ensured .

Junction temperature refers to the temperature of the semiconductor junction in the main heat-emitting part of the LED device. It is reflected in the working conditions of LED devices, can withstand the temperature value. Chip and phosphor heat resistance is still very high, has reached the chip junction temperature at 150 ℃, the phosphor at 130 ℃, the basic life of the device will not have any effect. The higher the chip phosphor heat resistance, the lower the thermal requirements. Temperature rise there are several different temperature rise, we are discussing here is: Case - ambient temperature it refers to the LED(LED bulbs energy saving china) device package (LED lamps can be measured the hottest spot) Temperature and environment (in the light emitting plane, 0.5 meters away from the lamp) temperature difference.

Reduce heating, as far as possible the use of good thermal conductivity of the cooling material, the design requirements have better ventilation channels, so that the heat dissipated as soon as possible, the required temperature should be less than 30 ℃. In addition, to improve the cooling of modular lighting should mention the agenda up. Many ways to dissipate heat, such as the use of heat pipes, of course, very good, but to consider the cost factor, the cost should be considered in the design issues.

In addition, LED lighting design in addition to improve lamp efficiency, light distribution requirements, beautiful appearance, to improve the heat level, the use of good thermal conductivity of the material, the radiator coated with certain nano-materials, the thermal conductivity increased by 30%. In addition, to have better mechanical properties and tightness, but also dust-proof radiator, LED lamps require temperature rise should be less than 30 ℃.

If you want to know more information, you can click LED light bulbs manufacturer china.

+

+